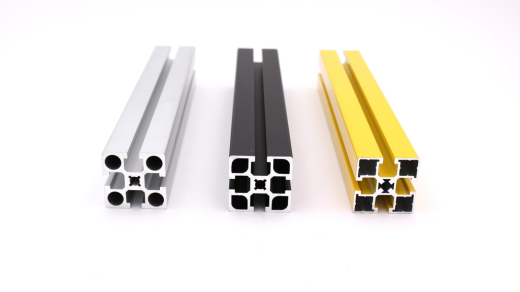

Every machine setup needs the right support structure, especially when safety and longevity matter. Choosing the wrong material can mean extra maintenance, replacements, or worse—downtime. That’s where MiniTec aluminum framing material stands out with smart design, clean lines, and built-to-last performance.

Easy Assembly and Disassembly

Building with MiniTec aluminum frame kit is like working with a grown-up version of building blocks—simple, precise, and tool-friendly. Each part connects using a clever T-slot design, so assembly doesn’t require welding, grinding, or a deep tool chest. Adjustments and replacements are quick, meaning less time spent modifying and more time keeping your systems running.

Disassembly is just as smooth. If a layout needs to change or a section must be relocated, the frame breaks down without damage. This gives teams flexibility and keeps materials reusable, which cuts costs over time. Traditional materials can’t match the efficiency that MiniTec aluminum framing offers for machine guarding setups that evolve with production needs.

Fully Adjustable Design

Change is constant on the shop floor, and machine guarding has to keep up. A fixed structure can slow operations or create unsafe blind spots. With MiniTec extruded aluminum framing, every piece can be adjusted without starting from scratch. That’s huge for adapting to new equipment, expanding work areas, or repositioning safety zones.

What makes this system especially valuable is the built-in adjustability. T-slot grooves let users slide components, add accessories, or reconfigure guards without drilling new holes or scrapping material. It gives manufacturers room to think ahead—and build smarter.

Rapid Assembly

Speed is everything in production. Lost hours during assembly can throw off entire timelines. With a MiniTec aluminum frame kit, rapid setup becomes part of the process. The modular design allows teams to pre-assemble sections off-site and then quickly bolt them together on location.

Even for custom builds, parts align accurately thanks to the precision of the profiles and connectors. There’s no cutting corners or retrofitting—everything fits the first time. That kind of efficiency keeps installation fast and stress-free, especially in time-sensitive projects.

Lightweight but Strong

Don’t let the clean, minimalist look fool you—MiniTec aluminum framing material is built to take a hit. It’s strong enough to handle high loads and endure vibrations, yet light enough for easy handling. That balance between strength and weight makes it ideal for guarding machines that require robust barriers without bulky construction.

Because the frames weigh less than steel, transport and installation are easier, too. One person can often manage frame sections solo. That reduces labor and risk while still delivering the safety and durability needed on the factory floor. It’s a win for both the team and the timeline.

Precision and Adaptability

MiniTec extruded aluminum framing is cut with incredible precision, which matters a lot in machine guarding. A poorly fitted frame can leave gaps or create weak points. MiniTec’s tolerances are tight, so every panel, bracket, and corner fits exactly as it should, maintaining the safety zone’s integrity.

Adaptability comes built in. From door mounts to sensor brackets and custom enclosures, the frame can take on new features easily. There’s no need to overthink future expansions because the structure grows with your needs. That adaptability makes it a long-term solution in a constantly shifting workspace.

Corrosion Resistance

Moisture, chemicals, and wear-and-tear are normal in industrial settings. But rust and corrosion aren’t. Unlike painted steel, MiniTec aluminum framing material naturally resists corrosion. That keeps the structure looking sharp and performing reliably for years without the need for constant touch-ups or replacements.

This resistance means less maintenance and fewer failures. It’s also safer—corroded structures can weaken without warning. Aluminum doesn’t just look cleaner; it works cleaner too. It’s ideal for cleanroom setups, food-grade environments, and anywhere hygiene or aesthetics matter alongside functionality.

Versatility

Machine guarding is just the beginning. The same MiniTec aluminum frame kit used to build a safety barrier today might become a workstation or mobile cart tomorrow. That kind of versatility means fewer limits—and fewer headaches when layouts change or new machines roll in.

Because it works with a wide range of accessories and parts, MiniTec aluminum framing adapts to almost anything. Whether it’s a full enclosure, sliding gate, or workstation with integrated lighting, the system scales easily. That modular flexibility means teams don’t just build once—they build better each time.