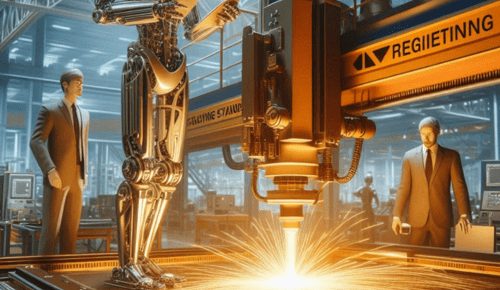

Plasma cutting has long been a trusted method in metal fabrication, but advancements in robotics are taking it to new levels of accuracy and efficiency. Across Alabama, robotics engineering companies are integrating intelligent automation into plasma cutting processes, transforming the way manufacturers handle complex designs. With precision technology, businesses are seeing improved speed, reduced waste, and cleaner cuts that outperform traditional methods.

How Robotics Companies Are Refining Plasma Cutting Accuracy in Alabama

Alabama robotics engineering companies are redefining precision in plasma cutting by developing advanced robotic arms and automated control systems. These systems allow for seamless, consistent movement, reducing human error and achieving pinpoint accuracy in every cut. By integrating high-tech sensors and AI-driven adjustments, robotics engineering companies in Alabama are making sure that even the most intricate designs come out flawless.

Beyond accuracy, robotic plasma cutting enhances repeatability. Traditional plasma cutting relies heavily on an operator’s skill, but robots maintain consistent quality from the first cut to the last. This innovation is especially valuable in industries requiring high-volume production, where maintaining exact specifications is essential. With robotics handling the cutting process, businesses can reduce material waste and increase productivity without sacrificing precision.

Intelligent Systems Delivering Ultra-Clean Cuts with Minimal Waste

One of the biggest advantages of robotic plasma cutting is its ability to create ultra-clean cuts with minimal waste. Robotics engineering companies in Alabama are integrating intelligent software that automatically adjusts settings based on the material type and thickness, ensuring the most efficient use of resources. These systems optimize the cutting path to minimize scrap, helping manufacturers lower costs while improving sustainability.

In addition to reducing waste, robotic plasma cutters significantly improve edge quality. Older cutting methods often leave rough edges that require additional finishing work, increasing production time and labor costs. With robotic precision, cuts are smooth and ready for assembly immediately, reducing the need for secondary processing. This means faster turnaround times and higher-quality finished products.

Could Robotic Automation Solve Your Plasma Cutting Efficiency Issues?

Many manufacturers struggle with inefficiencies in plasma cutting due to manual errors, inconsistent performance, and downtime. Robotics engineering companies in Alabama are solving these challenges by designing automated systems that streamline operations. With robotic plasma cutters, businesses can handle larger workloads while reducing reliance on skilled labor, ensuring production runs smoothly even during labor shortages.

Robotic automation also increases machine uptime. Unlike human operators who need breaks and experience fatigue, robotic plasma cutters work continuously, maximizing productivity. These automated systems detect potential issues before they become major problems, minimizing downtime and keeping production schedules on track. For companies facing bottlenecks in their manufacturing process, investing in robotic plasma cutting could be the key to improving efficiency.

Alabama Robotics Engineers Making Complex Shapes Easier to Achieve

Creating intricate designs and complex shapes in metal cutting can be a difficult task when relying on traditional methods. However, Alabama robotics engineering companies are making it easier with advanced robotic plasma cutters designed for extreme precision. Whether it’s detailed custom fabrications or highly technical industrial components, robotic systems can execute designs that would be nearly impossible to achieve manually.

By utilizing sophisticated motion control and high-speed processing, robotic plasma cutters navigate complex patterns with ease. These systems can cut intricate designs with absolute consistency, whether for decorative architectural pieces, specialized automotive parts, or aerospace components. With automation refining the process, businesses can expand their design capabilities without sacrificing accuracy or efficiency.

Precision Robotics Transforming Production Timelines Through Plasma Cutting

Manufacturers are always looking for ways to reduce lead times, and robotic plasma cutting is proving to be a game-changer. Robotics engineering companies in Alabama are implementing cutting-edge automation that accelerates production without compromising on quality. By eliminating manual handling errors and optimizing cutting sequences, these systems allow businesses to produce parts faster and more efficiently.

Automation doesn’t just speed up cutting—it also reduces setup times. Unlike traditional plasma cutting that requires frequent adjustments and manual recalibrations, robotic systems operate with pre-programmed precision. This means less downtime between production runs and the ability to handle multiple projects without slowing down operations. Companies that adopt robotic plasma cutting can keep up with increasing demands while maintaining strict quality standards.

Are Robotic Plasma Cutting Solutions the Secret to Lowering Manufacturing Costs?

High production costs can put pressure on manufacturers, but robotics engineering companies in Alabama are helping businesses cut expenses through robotic plasma cutting. These automated systems reduce labor costs by minimizing the need for highly skilled manual operators, allowing businesses to allocate resources more efficiently. Additionally, automation decreases material waste, further lowering expenses associated with raw materials.

Robotic plasma cutting also improves energy efficiency. Compared to older cutting methods, robotic systems optimize energy usage by ensuring that each cut is performed with minimal excess power. This leads to long-term savings on operational costs while supporting environmentally friendly manufacturing practices. By adopting robotic plasma cutting, businesses can stay competitive in a market that demands both cost-efficiency and high-quality production.

Enhanced Robotics Providing Consistency Beyond Human Capability

One of the most significant benefits of robotic plasma cutting is its ability to provide consistency that surpasses human capability. Alabama robotics engineering companies are developing systems that eliminate variations in cut quality, ensuring that every piece meets the same high standard. This is particularly valuable for industries that require tight tolerances and uniformity across large production runs.

Unlike manual cutting, which can be affected by fatigue or slight variations in technique, robotic plasma cutters deliver the same level of accuracy every time. These systems operate with millisecond precision, adjusting in real-time to maintain exact cutting conditions. For manufacturers who need dependable results without variation, robotic plasma cutting is setting a new standard for reliability and quality.